At around 2:00 am on June 28, 2018, a hazardous chemical vehicle loaded with 33.5 tons of iso octane collided with a cement trailer at a distance of 100km+700m in Yingshang County, Fuyang City (Shibalipu Town) on the 102 line, causing 8 deaths, 3 injuries, and direct economic losses of more than RMB 10.517 million.

scene of an accident

At around 19:20 on the day before the incident, the driver Fei Shikai drove the Yu ND1362 heavy-duty semi-trailer tractor (towing the Yu NU497 heavy-duty tank semi-trailer), carrying the hazardous chemical isooctane from Xuancheng City to Heze City, Shandong Province. At around 1:40 am on the day of the incident, in accordance with the regulation that hazardous chemical vehicles are not allowed to drive on the highway from 2:00 am to 5:00 am, they drove out of the Yingshang toll station on the Chuxin Expressway and entered the 102 line, then drove along the Guanzhong Avenue in Yingshang County from east to west. At around 2:08 am, the vehicle arrived at a flat corner of the "Y" - shaped intersection at a distance of 100km+700m (People's Bridge, Shibalipu Town) on Line 102. Due to a misjudgment of the traffic signal lights at the intersection, the vehicle slowed down and stopped, waiting for passage.

At around 21:00 on the day before the incident, the driver Du Yingting drove a heavy-duty semi-trailer tractor with license plate number Wan K61273 (towing an unlicensed assembled semi-trailer) to the Yueyunkui coal gangue yard in Baiying Village, Fengtai County to load the stone. At around 24:00, he left and entered the 102 line heading towards Funan County. At around 2:08 am, the rear of the vehicle collided with the Yu ND1362 heavy-duty semi-trailer tractor (towing the Yu NU497 heavy-duty tank semi-trailer), causing a leak and subsequent explosion of iso octane on the left side of the rear of the vehicle. This instantly ignited the Wan K5J106 heavy-duty cement semi-trailer tractor (towing the Wan KEF60 trailer), which was parked in the same left lane waiting for the signal light to turn left.

At the same time, the open flame quickly ignited the residential houses on the north side of the incident road, causing a total of 8 deaths, including 2 drivers (Du Yingting, Lin Qikun) and 6 residents in the residential houses. Three residents in the residential building were injured, three vehicles were burned down, and three houses and their contents were damaged to varying degrees. The youngest victim was only one year old.

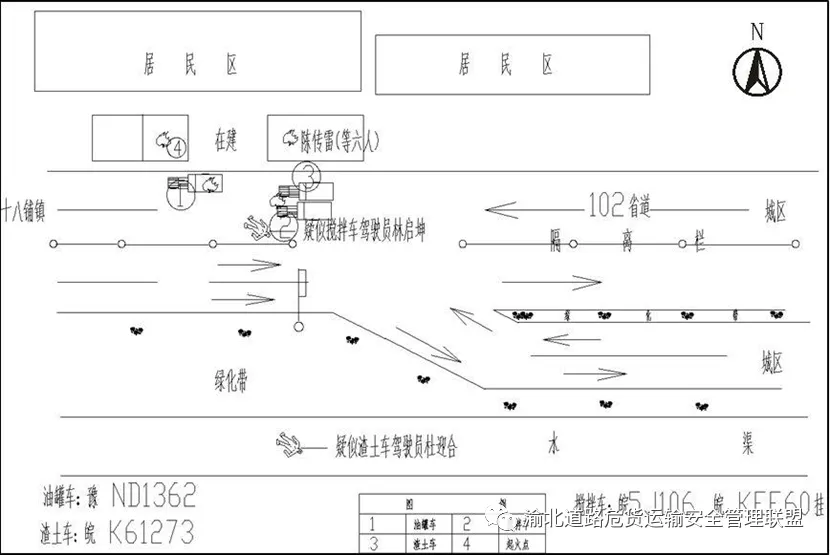

Schematic diagram of the accident scene plan

The direct cause of the accident was that the driver Fei Shikai was fatigued at night and driving a flammable and explosive hazardous chemical vehicle with a reflective label at the rear that did not meet the standard requirements. When encountering a traffic signal green light, the vehicle suddenly stopped due to misjudgment. The illegal assembled trailer purchased by the owner Xu Dong, who was driving with the driver Du, was overloaded and speeding on the road. Improper handling of the emergency situation collided with the hazardous chemical vehicle parked ahead, causing the iso octane loaded on the hazardous chemical vehicle to leak from its rear and explode instantly, resulting in significant casualties.

The indirect cause of the accident is that the owner unit of the accident vehicle did not fulfill its main responsibility for safety production, and the relevant party committees, governments, departments, and units did not properly manage the reconstruction projects of national and provincial trunk highways and road traffic safety within their jurisdiction, resulting in a major road traffic production safety responsibility accident.

1. The reflective markings at the rear of hazardous chemical vehicles do not meet the standards; 2. Illegal assembly of trailers without inspection, overloading and speeding driving; 3. Unreasonable setting of traffic lights and ineffective investigation and disposal of hidden dangers by the traffic police brigade have been held accountable; 4. The housing and construction department did not set up and construct highway traffic signals according to standards; 5. The land acquisition and demolition are not in place, and there are a large number of residential houses along the expanded highways that do not meet the safety distance standards.

Accident section

Responsibility determination: The responsible persons for the accident, Fei Shikai, Xing Shulong, and Xu Dong, shall be transferred to the judicial authorities, and Du Yingting shall be exempted from criminal responsibility for his death in the accident;

Three responsible persons of Chunlei Logistics Transportation Co., Ltd. in Funan County, a business unit related to the accident, shall be subject to administrative penalties respectively;

Nine individuals related to the accident, including the deputy county magistrate of the government and department (unit), will be given corresponding disciplinary actions and organizational processing;

Require the Public Security Bureau and Housing and Urban Rural Development Bureau of Yingshang County to conduct written inspections to the Yingshang County Government, the Fuyang City Highway Management Bureau to conduct written inspections to the Fuyang City Transportation Bureau, the Yingshang County Government and Fuyang City Transportation Bureau to conduct written inspections to the Fuyang City Government, and the Fuyang City Government to conduct in-depth written inspections to the provincial government. At the same time, it is recommended that the Henan Provincial Emergency Management Department conduct a thorough investigation into the performance of Jinyuan Logistics Co., Ltd. and relevant departments in Shangqiu City, Henan Province.

Scene map after 3 residential houses on the north side of the incident road were ignited

It is reported that the hazardous chemical transported by the accident vehicle was iso octane, which burned violently at the time of the incident, with flames reaching more than 20 meters and accompanied by a 500 meter flowing fire.

Isooctane is a commonly used chemical and belongs to Class 3 hazardous materials.

Melting point: -107.4 ℃

Boiling point: 99.3 ℃

Flash point: -3 ℃

Density: 0.6919 (20 ℃)

Used as an additive for aviation gasoline and other fuels, it is highly prone to detonation.

Operating Procedures for Isooctane Loading

In order to ensure safety and efficiency during transportation and storage, strict operating procedures must be followed:

1、 Preparation before loading

1. Vehicle inspection: Before loading, a comprehensive inspection of the transport vehicle must be conducted. Check the tires, brake system, lights, etc. of the vehicle to ensure their normal working condition.

2. Prepare tools and equipment: Prepare the necessary loading and unloading tools and equipment, including pump stations, hoses, anti-static grounding wires, etc. Ensure that these devices are in good condition and undergo regular maintenance.

3. Determine loading capacity: Determine the amount of iso octane to be loaded based on customer requirements and transportation restrictions, and ensure that it does not exceed the carrying capacity of the transport vehicle.

2、 Operating procedures

1. Electrostatic protection measures: Electrostatic protection measures must be taken before starting loading. Connect the anti-static grounding wire to the transport vehicle and storage tank, and ensure good contact.

2. Device connection: Connect the hose to the storage tank and pump station, ensuring a secure and leak free connection. Use professional sealing materials such as rubber gaskets to ensure good sealing at the connection.

3. Open the storage tank valve: After the device is connected, slowly open the storage tank valve and observe for any abnormal phenomena. If any abnormalities are found, the loading should be stopped immediately and inspected.

4. Open the pump station: After confirming that the storage tank valve is normal, slowly open the pump station and gradually increase the pumping pressure. Pay attention to observing whether there are any abnormal conditions in the pump station and hoses. Pay attention to dangerous chemical escort agencies and learn about dangerous transportation safety knowledge.

5. Monitoring flow rate: During the loading process, the flow rate of isooctane should always be monitored. Adjust the pumping pressure according to customer needs and transportation restrictions to ensure stable and compliant flow.

6. Close the pump station and storage tank valves: When the loading capacity reaches the required level, the pump station should be closed first, and then the storage tank valves should be closed. Ensure that there is no odor or leakage when closing.

3、 Security measures

1. Fire extinguisher preparation: During the loading process, a sufficient number of fire extinguishers must be prepared and placed near flammable areas. Fire extinguishers should undergo regular inspection and maintenance to ensure their proper functioning. Extinguishing agent: use water mist, dry powder, foam or carbon dioxide extinguishing agent to extinguish the fire. Avoid using direct current water to extinguish fires, as direct current water may cause the splashing of flammable liquids and spread the fire. 2. Use of fire extinguishers: In case of fire or leakage accidents, fire extinguishers should be used immediately to extinguish them. Pay attention to using the correct fire extinguishing agent and follow the operating instructions.

3. Emergency handling: In the event of a leak or other emergency situation, appropriate measures should be taken immediately. Quickly close valves, evacuate personnel, and promptly report to relevant departments.

In the event of a leak, all ignition sources should be immediately eliminated. Designate a warning zone based on the impact area of liquid flow and vapor diffusion, and evacuate unrelated personnel from crosswind and upwind directions to a safe zone. It is recommended that emergency personnel wear positive pressure self-contained breathing apparatus and anti-static clothing. All equipment used during homework should be grounded. Do not come into contact with or cross over leaked materials. Cut off the leakage source as much as possible. Prevent leakage from entering water bodies, sewers, basements, or enclosed spaces.

Minor leakage: Absorb with sand or other non combustible materials. Collect absorbent materials using clean, non sparking tools.

Massive leakage: Construct embankments or dig pits to contain it. Cover with foam to reduce evaporation. Spray mist can reduce evaporation, but it cannot reduce the flammability of leaked materials in confined spaces. Transfer to a tanker or dedicated collector using an explosion-proof pump. Pay attention to dangerous chemical escort agencies and learn about dangerous transportation safety knowledge.

4. Personal protection: During operation, appropriate personal protective equipment must be worn, such as gloves, goggles, anti-static clothing, etc. Ensure the safety of staff.

4、 Cleaning and maintenance

1. Cleaning the vehicle: After loading, the transport vehicle must be cleaned. Remove residual iso octane and other pollutants to ensure the vehicle is clean and tidy.

2. Equipment maintenance: Inspect and maintain used loading and unloading tools and equipment. Repair or replace damaged or aged components and keep the equipment in good condition.

3. Waste disposal: Properly dispose of waste and comply with environmental regulations. Hand over waste to professional units for disposal to reduce its impact on the environment.

Summary: The purpose of the isooctane loading operation procedures is to ensure safety and efficiency during the loading process. During the preparation phase before loading, it is necessary to inspect the vehicle and prepare the necessary tools and equipment. In the operation program, attention should be paid to steps such as electrostatic protection, device connection, and flow monitoring. Safety measures include preparing fire extinguishers, emergency handling, and personal protection. During the cleaning and maintenance phase, vehicles, equipment, and waste should be properly disposed of. By following these regulations, the safety and efficiency of isooctane loading operations can be effectively improved.